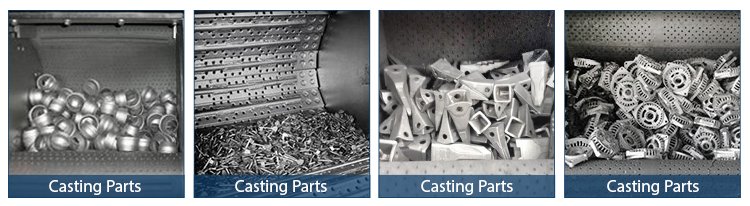

Mesh belt shot blasting machine is a kind of functional shot blasting equipment for cleaning shackles and other disc, sheet, castings, machine bodies, and structural parts. The mesh belt shot blasting machine can apply strong shot blasting to the surface of the steel and castings in the original state to remove the rust layer, welding slag and oxide scale on it, so that it can obtain a uniform metallic luster, so as to improve the quality of the coating of the steel. Anti-corrosion effect.

The cleaning and strengthening of the mesh belt shot blasting machine is a cold treatment process, that is, the motor drives the shot blasting machine to continuously hit the surface of the part with countless small circular media called steel shots. Each steel shot hits the metal part, like a miniature rod hitting the surface, making small indentations or depressions. In order to form depressions, the metal surface layer must be stretched. Under the surface layer, the compressed crystal grains try to restore the surface to its original shape, thereby producing a hemisphere under the action of high compression force. Numerous depressions overlap to form a uniform residual compressive stress layer, which further improves the indicated hardness and fatigue resistance of the workpiece. Can significantly extend the service life of the workpiece.

The mesh belt on the mesh belt shot blasting machine is the main part of the machine. The biggest advantage is that it can continuously convey and process various sizes of related workpieces; the material of its parts is made of manganese steel, which not only has very high wear resistance, but also It can also ensure a very long maintenance and replacement cycle, which reduces the cost of the overall use of the machine; coupled with the multi-width mesh belt size, the machine can be used for cleaning a variety of different workpieces.