Steel plate shot blasting machine is a kind of shot blasting derusting equipment produced by us, which can effectively remove the rust spots, rust layer, oxide scale and other dirt and impurities on the surface of the steel plate. The steel plate is shot blasted at one time, and the surface of the steel plate is refurbished to the original light metal color. The surface of the cleaned steel plate shows a certain degree of roughness, which is conducive to the subsequent painting process. Below we will introduce the steel plate shot blasting machine in detail for you.

The use characteristics of steel plate shot blasting machine.

1. Two methods are used: through type and hanging chain type. The through-type roller conveyor is used to transport the steel plate to the shot blasting room, and the hanging chain type uses catenary guide rails to clamp the steel plate to travel. The former has high work efficiency, while the latter takes up a small space.

2. According to the requirements of workload and cleaning effect, 4 or 8 shot blasting devices are usually configured. If the user's workload is large, more shot blasting devices can be added.

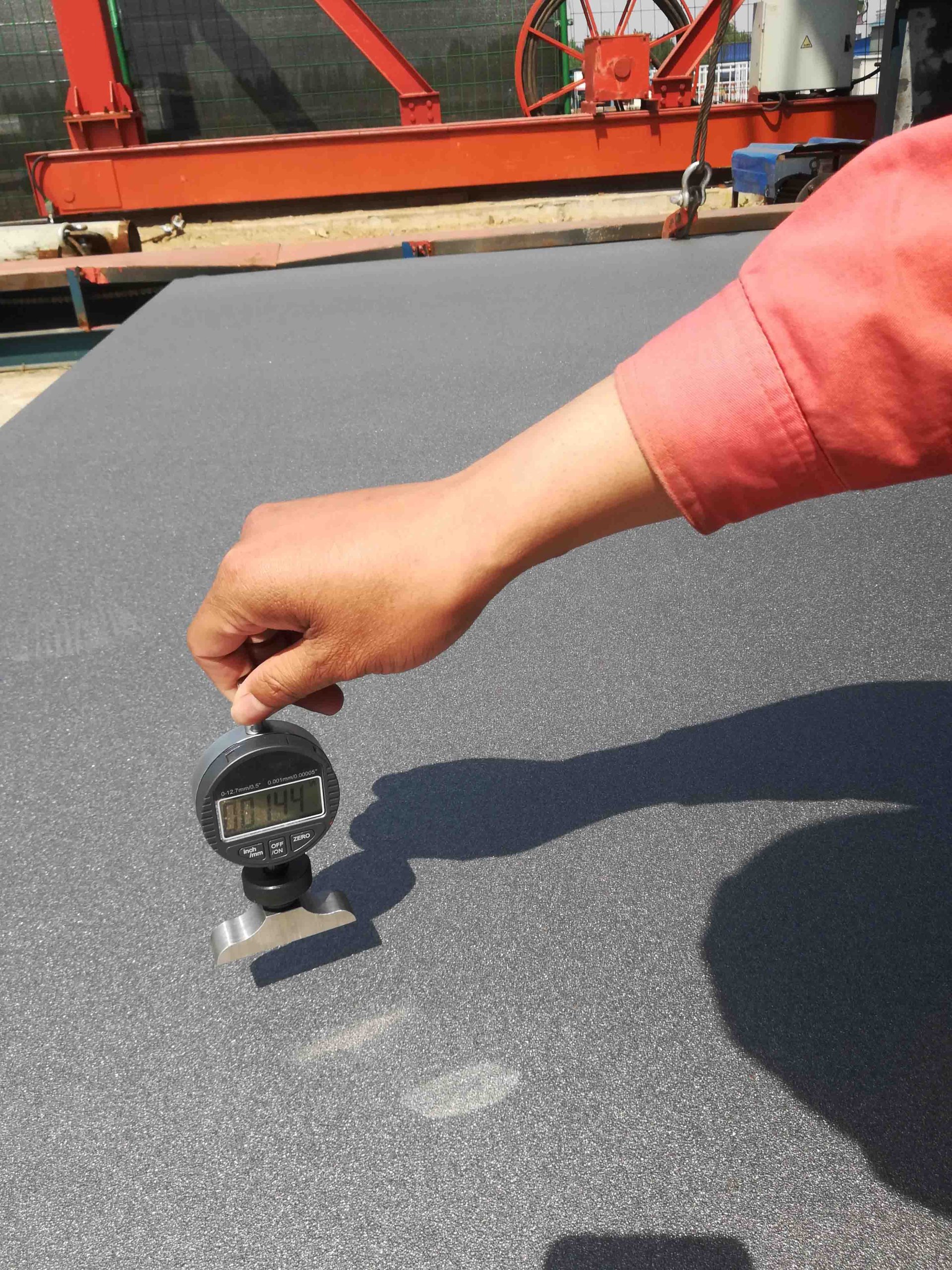

3. The rust removal level of the steel plate rust remover reaches Sa2.5 or above.

4. High level of automation, saving labor costs. The only place where manual intervention is needed is to operate the electrical control cabinet and load and unload objects.

5. The cleaning effect is good, and the high-efficiency pulse filter cartridge dust collector is used to collect dust, which does not pollute the environment.